2023-02-11

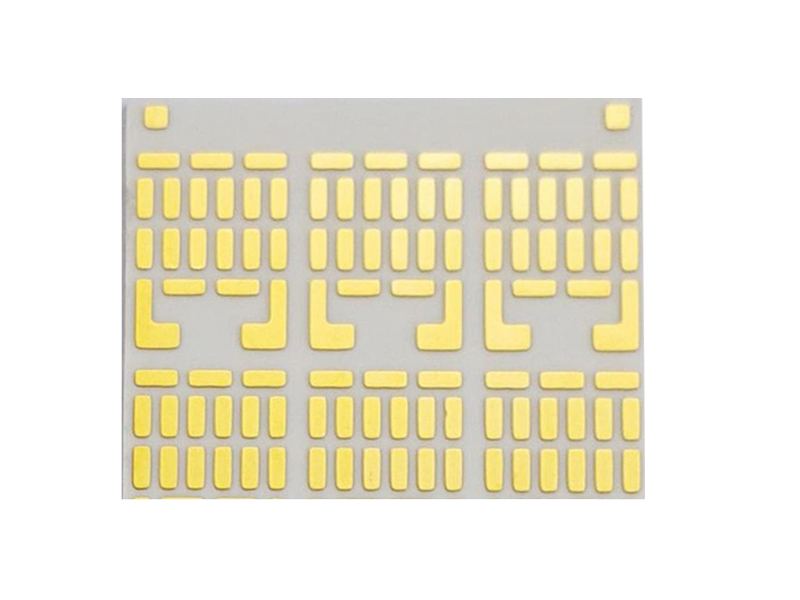

Layers: 1

Surface treatment: immersion gold

Special process: ceramic base

Material: 96% AL2O3

Line width/line spacing: 7/3.5mil

Thermal conductivity of insulating layer: 30W

Plate thickness: 0.635+/-0.1mm

Mini aperture: 0.2mm

Customer background

Company Location: America

Application:Aerospace

Field:Pressure Sensor

Service: AL2O3 Ceramic PCB Manufacturing

Project challenge

The customer requires delivery within 8 days.

It takes a little time to make EQ and confirm the working Gerber, and using the thick film process and the silver palladium line conductor. The entire production time is relatively urgent.

How to serve?

Pulse laser or continuous laser can be used in laser processing for cutting holes, and pulse laser is generally used for scribing to reduce the thermal impact of laser partial heating on ceramic substrates.

The silver paste forms a circuit on the surface of the alumina ceramic substrate through the screen printing process, and the organic components in the silver paste are discharged through sintering. At the same time, the glass and silver powder are softened, and the silver is bonded to the alumina ceramic substrate to form a circuit.

The substrate is sintered at a high temperature of 850~900°C during processing.

Results and Benefits

The manufacture of ceramic circuit boards was completed within the stipulated time, and the products were shipped to customers smoothly.

The customer is very satisfied with our service, and our company also produces for him in mass production.

Jennifer

I am Jennifer, sales team leader of Best Technology, 5 years’ experience in PCB. If you want to custom Ceramic PCB and PCBA, please feel free to contact me to ask any questions.

We not only provide flexible board, Metal core PCB, ceramic PCB, rigid-flex circuit and FR4 PCB manufacturing, but also include PCB copy board service, reverse engineering and Gerber design, component management and procurement solutions