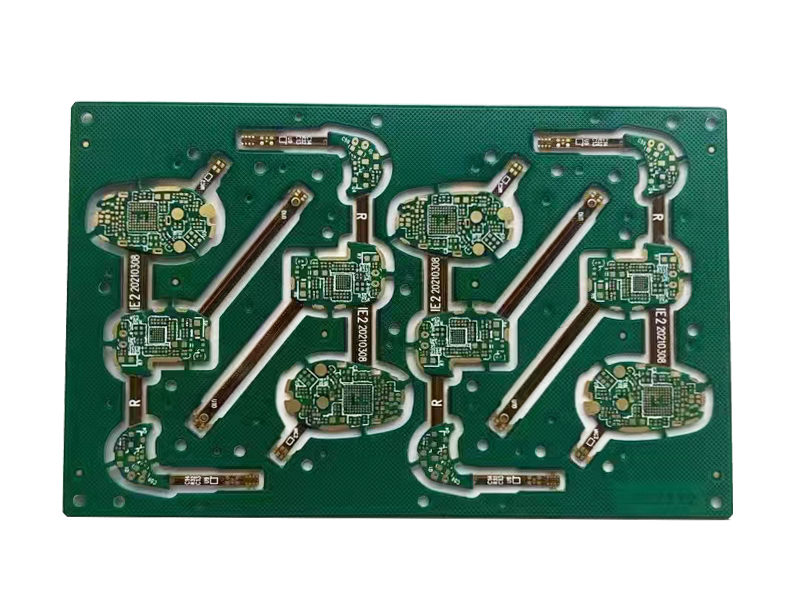

Rigid-Flex PCB

Rigid-flex PCBs are flexible circuit boards and rigid circuit boards, which are combined according to relevant process requirements after lamination and other processes to form a circuit board with FPC characteristics and PCB characteristics.

It can be used in some products with special requirements. It has both a certain flexible area and a certain rigid area. It is of great help to save the internal space of the product, reduce the volume of the finished product, and improve the performance of the product.

Rigid-Flex PCB Capabilities

| Item | Fabrication Capabilities |

| The number of layers | 2-48 layers |

| FPC main substrate | Taiflex,Gracethw,Shengyi,Songrun |

| PCB material | Shengyi,ITEQ,KB,FR4 |

| Board Thickness | 0.25-6mm |

| Min Width/Spacing | 0.05mm/0.05mm |

| Maximum Rigid-flex PCB Size | 230*500mm |

| Minimum Rigid-flex PCB Size | 5*8mm |

| Insulation Thickness | 12.5um,25um,50um |

| Copper foil thickness | 12um,18um,36um,70um |

| Stiffener material | FP4,PI, PET, SUS,PSA |

| Min drilling diameter | Mechanical drilling: 0.15mm, laser drilling: 0.1mm |

| Via Tolerance | NPTH:±0.05mm PTH:±0.075mm |

| PI Thickness | 0.5mil,0.7mil,0.8mil,1mil,2mil |

| Min weld ring | Inner:5mil Outer:4mil |

| Min stiffener size | 4*5mm |

| Max stiffener size | 32*32mm |

| Stiffener Alignment accuracy | ±0.075mm |

| Character to Pad | 0.15mm |

| Etching Tolerance | ±20% |

| Surface Finishing | ENIG, Flash Gold, Hard Gold Finger, Gold Plating(50mil), Gold finger,Selected Gold Plating, ENEPIG, ENIPIG, HAL, HASL(LF), OSP, ImAg, ImSn |

| Solder Mask color | Green ,Red, Yellow, Blue, White ,Black, Matte black, Violet and any color you need |

| Silkscreen color | White, Black, no silkscreen |

| Test and Certificate | Fly Probe Testing (Free) and A.O.I. testing(free), ISO 9001:2008 ,UL Certificate |

Rigid-flex PCB Material

| Item | Characteristic |

| Brand | Dupont / Doosan / Grace / SYL / Tailfex / ThinFlex |

| Base material | PI,FR4 |

| Material Thickness | 0.10mm / 0.12mm / 0.15mm / 0.20mm / 0.25mm / 0.30mm / 0.40mm / 0.50mm / 0.60mm/ 0.80mm /1.0 mm/ 1.2 mm / 1.6mm / 2.0 mm |

| Cover lay Type | PI and Solder mask |

| TG Value | 130℃、150℃、170℃ |

| Halogen Free | Yes(optional) |

| ROHS | Yes |

| Flammability rating | 94-v0 |

| Dielectric Strength | >=1.3 KV/mm |

| Wrap & Twist | ≤ 1% |

Rigid-flex PCB Prototypes Lead Time

| Prototype(<3m²) | Layer counts | Normal delivery | Urgent orders |

| Rigid-flex PCB | 2 layers | 8-14 Days | 1 Week |

| 3 layers | 14-16 Days | 8 Days | |

| 4 layers | 15-20 Days | 10 Days | |

| 6 layers | 20-25 Days | 12 Days | |

| 8 layer | 1 months | 15 Days |

Rigid-flex PCB Mass Production Lead Time

| Mass Production | Layer counts | Normal delivery | Urgent orders |

| Rigid-flex PCB | 2 layers | 15-18 Days | 1.5 Weeks |

| 3 layers | 18-23 Days | 2Weeks | |

| 4 layers | 25-30 Days | 2.5Weeks | |

| 6 layers | 28-35 Days | 3Weeks | |

| 8 layer | 1.5 months | 3.5Weeks |

Talk to a PCB Manufacturer Expert today

We look forward to working with you side by side, to be a long-term partner whom you can trust.