2023-02-11

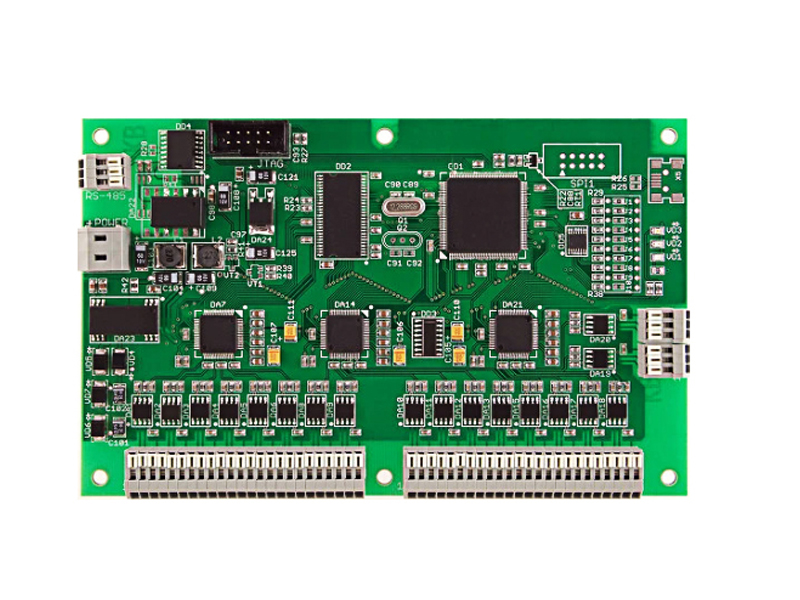

Layers: 4

Surface treatment: immersion gold

Special process: hole in the plate

Material: FR4 S1141

Line width/line spacing: 8/8mil

Plate thickness: 1.0mm

Copper thickness:1OZ

Minimum aperture: 0.4mm

Customer background

Company Location: Mexico

Application:Medical Device

Field: Medical Monitor

Service: FR4 PCB Manufacturing,PCB Assembly

Project challenge

The customer requested fast delivery and high quality production of 500PCS so that they can be put into the market quickly.

One board requires 125 electronic components,there are 52 types of PCBA processing components all of which we can provide, but inventory is a new challenge.

The minimum package size of SMT patch components is 0603.

How to serve

1. Provide one-stop service, including PCB, SMT/PCBA and functional testing, etc.

2. The advantages of centralized procurement help our customers effectively reduce procurement costs and increase product benefits.

3. 24 hours technical support.

4. Purchase critical components in advance to help customers avoid the risk of shortage issues.

5. Channels of many suppliers can support and meet different procurement needs

Results and Benefits

3 fully automatic SMT placement production lines have a daily SMT production capacity of more than 5 million points, and the delivery time is 15 days, which can be delivered to customers quickly.

Before shipment, X-RAY detector, first article tester, AOI automatic optical detector, BGA will be carried out

Rework station.

The smallest package that can be attached is 0201, and the accuracy can reach ±0.04mm. The smallest device accuracy can mount PLCC, QFP, BGA, CSP and other devices, and the pin spacing can reach ±0.04mm.

Linda

I am Linda, sales team leader of Best Technology, 5 years’ experience in PCB. If you want to custom PCB and PCBA, please feel free to contact me to ask any questions.

We not only provide flexible board, Metal core PCB, ceramic PCB, rigid-flex circuit and FR4 PCB manufacturing, but also include PCB copy board service, reverse engineering and Gerber design, component management and procurement solutions