2023-02-11

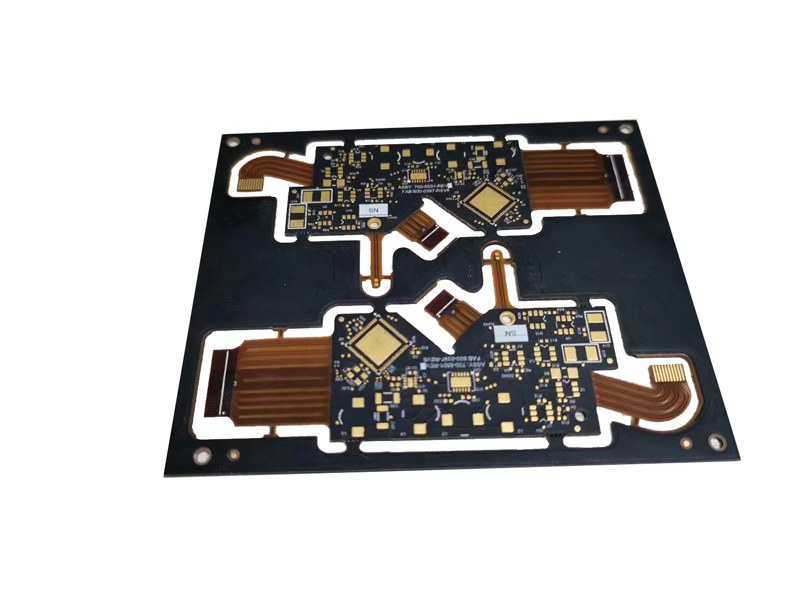

Layers: 8

Surface treatment: immersion gold+osp

Special process: 2+ HDI

Material: FR4 S1000-2

Line width/line spacing: 3/3mil

Plate thickness: 1.2mm

Copper Thickness: 2Oz

Minimum aperture:0.10mm

Customer background

Company Location:Europe

Application: Mobile communications

Field: Communication Equipment

Service: HDI PCB Manufacturing

Project challenge

The customer certification procedures for high-layer circuit boards are strict and cumbersome, so the entry threshold for high-level circuit boards is relatively high, and the industrialized production cycle is relatively long.

The difficulty is buried vias and plugged vias.

High-level circuit boards have the characteristics of thicker boards, more layers, denser lines and vias, larger unit sizes, and thinner dielectric layers. Inner space, interlayer alignment, impedance control, and reliability requirements are more stringent.

How to serve

1. Provide free DFM inspection, professional engineers make EQ and working Gerber before production.

2.7*24 hours technical support.

3. A complete HDI equipment production line

4. HDI production is equipped with many professional engineers. Including laser drilling engineers, HDI lamination engineers, HDI full-process process engineers, line engineers, solder mask engineers, and senior engineering R&D personnel.

Results and Benefits

All of the products we produce for our clients are excellent and receive high levels of satisfaction and appreciation from them.

Material thickness and laser drilling are well controlled and meet customer requirements.

Fast delivery wins customers a lot of assembly time.

Cristina

I am Cristina, HDI PCB sales team leader of Best Technology, 5 years’ experience in PCB. If you want to custom PCB and PCBA, please feel free to contact me to ask any questions.

We not only provide flexible board, Metal core PCB, ceramic PCB, rigid-flex circuit and FR4 PCB manufacturing, but also include PCB copy board service, reverse engineering and Gerber design, component management and procurement solutions