2023-02-11

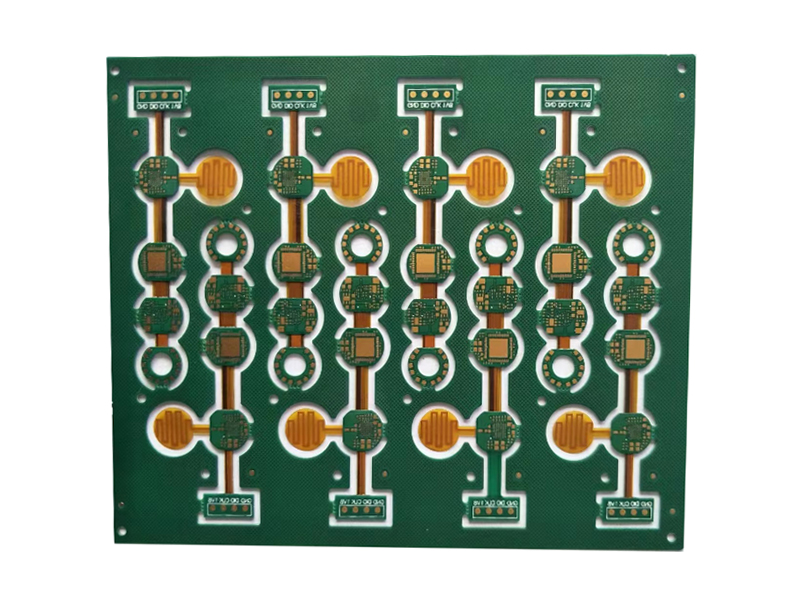

Layers: 6

Surface treatment: immersion gold

Special process:2R+2F+2R stackup

Material:FR4+PI

line width/line spacing: 5/5mil

Plate thickness: 1.0mm

Copper thickness:1OZ

Min aperture: 0.2mm

Company Location: America

Application: Medical Ventilator

Field: Medical Device

Service:Rigid-flex PCB Manufacturing

This is a 6-layer flexible and rigid board, and the stackup is a combination of 2R+2F+2R.

Customers require strict impedance matching requirements

This is a medical product, and all processes need to comply with ISO9001 and ISO13485 standards.

Customers need to conduct sample testing quickly, and the delivery time is 15-20 days.

Customers have higher requirements for expansion and contraction control.

The engineer team discussed how to control expansion and contraction, how to optimize the production process, and reduce the probability of scrapping risk.

Test the expansion and contraction performance of similar products in advance to ensure that there is no expansion and contraction problem in a specific environment.

Provide fast turnaround service, arrange fast production.

Professional sales follow up the order status, if there is any problem, we will feedback to the customer immediately.

Within 2 weeks we complete the sample production, and quickly ship to customers.

The customer's sample testing was very successful, saving time in releasing the end product. Improve the efficiency of the product.

I am Penny, sales team leader of Best Technology, 5 years’ experience in PCB. If you want to custom Rigid-flex PCB and PCBA, please feel free to contact me to ask any questions.

We not only provide flexible board, Metal core PCB, ceramic PCB, rigid-flex circuit and FR4 PCB manufacturing, but also include PCB copy board service, reverse engineering and Gerber design, component management and procurement solutions